Forklift controls vary depending on the type of truck. A certain type of forklift can have different operational controls from others. This is why before operating a forklift, it is important to familiarize yourself with the owner's manual where you can read the location of the controls and understand how each control works.

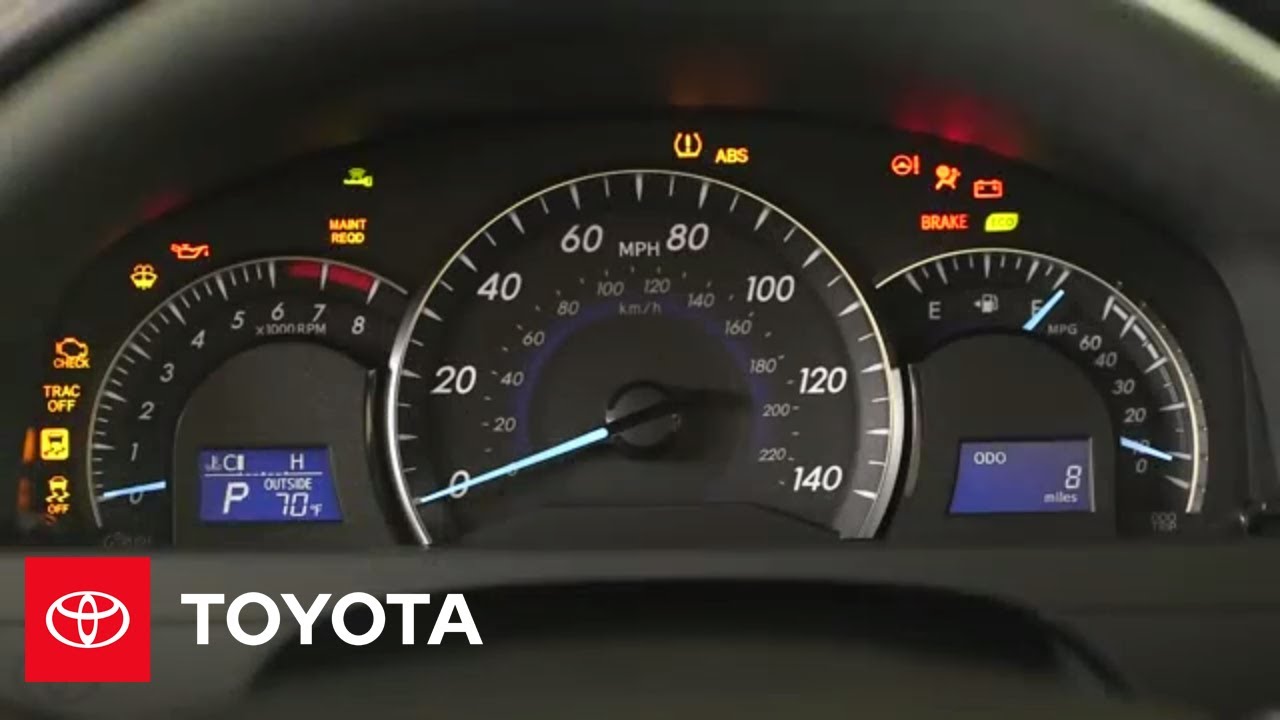

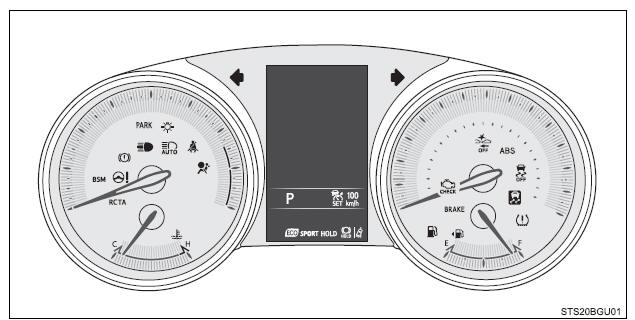

- Toyota Forklift Dash Symbols

- Toyota Forklift Dash Warning Lights Symbols

- Dashboard Symbols

- Car Dashboard Symbols

Kerry Toyota Specials Kerry $0 Down Lease Specials New Featured Vehicles Pre-Owned Featured Vehicles Toyota Employee Pricing Service Specials Parts Specials Compare Models. 2021 Toyota Corolla 2021 Toyota Camry 2021 Toyota RAV4 2021 Toyota Highlander Special Finance Programs. New And Certified Incentives College Grad Rebate Military Rebate. 97 acura cl service toyota 8-series internal combustion forklift bobcat toyota sas - system of active stability toyota 9701i2 manual toyota forklift truck dash warning lights - financial procedures sample toyota dashboard lights & symbols guide seapilot manual toyota dashboard indicators - jeff wyler toyota technicial shareme - free hyster. Download 80 Toyota Forklifts PDF manuals. User manuals, Toyota Forklifts Operating guides and Service manuals.

Hydraulic Lift Knobs – Forklift has three basic controls knobs. One that lifts the forks up or down, the second one tilts the forks/blades down or up to secure the load, and the third to move the load side to side.

Some types of forklifts have a knob that controls the width of the fork.

Toyota Forklift Dash Symbols

Forklift Directional Controls – This basically works just like the transmission of a car. If you want to park the car, you put it in “P” or park, if you want to drive the car, you put it in “D” or drive, and you want to reverse, you switch the transmission lever to “R.” But forklift directional control has only three positions, forward, neutral and reverse. Forklift directional controls can be steering column mounted or foot operated.

You Can Also Watch This Video:

Watching something is the best way to learn the skill, so here’s a Youtube video that explains how the hydraulic lift knobs and directional controls work.

Now, that you’ve finished watching the tutorial video on how to use the forklift control levers/knobs, here are the other controls you must familiarize with:

Accelerator Pedal – This gives a boost in speed and acceleration. It is self-explanatory.

Brake Pedal – Again, it is self-explanatory.

Clutch Pedal – Some type of forklifts are equipped with a clutch pedal that gives the operator more driving acceleration by shifting from gear to gear. Such forklifts equipped with clutch are those used outdoors and with an internal combustion engine.

Inching Pedal – The inching pedal is usually operated by the left foot. Its purpose is to make a very slow and little movement for maneuver with full engine power for lifting. Inching pedal is used commonly to maneuver forklift in tight spaces or corridors.

Parking Brake – Forklift is equipped with such brake and it works similarly in your car. It holds the forklift firmly when not in use. When parking in an inclined floor surface, engage the parking brake and block the wheel to make it more secure.

In another type of truck, such as the hydrostatic forklift, acceleration is done by pushing the pedal down and the more the pedal is depressed, the faster the forklift moves; to put the machine to a halt/stop, the operator releases the accelerator pedal. There is no brake control in a hydrostatic truck.

In other types of hydrostatic forklifts, there are two accelerator pedals that act like directional controls. The first pedal when pushed moves the forklift forwards, and the other one moves the truck in reverse. The operator shifts his foot from pedal to pedal to drive the forklift in the desired direction.

After Learning the Forklift Controls, Are You Ready Taking Forklift Training?

I assume that you are planning to take forklift training that’s why you are learning the forklift controls. If that’s the case, then we can you help find the forklift training school where you can take the training from and get certified in no time. You will also know the step by step process for enrolling in forklift training. Likewise, we have answers to your most commonly asked questions about forklift training, just the read topics or browse through the blog section.

At this website, we’ve prepared tutorials and a list of training schools specific to the location where you are to make everything convenient for you. Just browse the location at the left hand of the screen (if you are on a desktop computer) or in the lower portion of the screen (if you are on mobile).

Where Can You Learn How to Operate a Forklift?

If you’re a beginner who plans to operate a forklift as a career, there are several options you can go to:

Local Community College

Your local community college is one of the places where you can learn how to operate this equipment. They usually have a training schedule. The community college can be an ideal place to take the training not only because they have a lower cost but, in some circumstances, they offer it for free. If you short on budget, keep an eye on the schedule or make an inquiry with your local community college.

Equipment Rental Company

What I like about taking the forklift training at an equipment rental is that they have a wide range of forklift equipment. You have a variety of choices. If you want to choose a particular brand or model of forklift, the equipment rental company has it. Aside from that, they have a modern training facility and updated course curriculum that coheres to OSHA standards.

Heavy Equipment Training School

The heavy equipment training school has a wide range of training programs that cover forklifts and many types of heavy equipment such as tractors, loaders, dozers, etc. to prepare for a career in this field. If you’re serious about starting a profession in heavy equipment operation, find a school near you. Usually, you can start as an apprentice by applying to the union or begin an initial education by enrolling in a course.

Forklift Dealer

Forklift training can be given by the dealer. What I like about this is that the dealer has developed a training program suited for a specific type of forklift you want to get certified. The dealer has a highly trained instructor who knows different forklift equipment very well.

Tips on How to Drive a Forklift Safely

Toyota Forklift Dash Warning Lights Symbols

Having knowledge of driving a forklift safely can prevent accidents in the workplace. Below are some of the important tips you can employ, you may have heard or known these but still they’re not obsolete.

- First and foremost, the operator must be trained and certified first before operating this machine - The forklift training course should be specific to the type of forklift the operator is intending to operate. Taking the course and getting certified only takes a small amount of time to complete and a little investment to spend. Being certified has a lot of advantages.

- Appropriate clothing must be worn - PPEs such as a hard hat, luminous safety vest, steel-toed shoes, and eye protection are important especially when the environment is hazardous. Any loose clothing is not allowed as it can snag with the moving mechanism of the forklift.

- Pre-operational inspection must be performed – the daily inspection checklist must be updated to make sure that the forklift is in good running condition. The inspection involves checking brakes and hydraulic fluids, seeing if the warning devices and lights are functioning and ensuring the tires are not worn out. The inspection checklist has the details of all things to check. Any fault should be reported to the superior for immediate corrective action.

- The forklift should fully-charged (if it’s electric) or has enough fuel (if it’s gas or LPG-powered) - If the truck has not enough charge or fuel during operation, it could stop at any time or the truck’s lifting capacity could considerably decrease. What if the operator is lifting a 1-ton load when the truck suddenly stops because of insufficient fuel? This is when a serious accident could happen.

Dashboard Symbols

- Never lift a load that is beyond the lifting capacity – know the capacity of the forklift on the data plate, it is usually attached on the machine. It indicates all relevant information such as the model, year, manufacturer, capacity, fuel type, etc. Please do remember that lifting a load that is well beyond the capacity could cause tip-over. Overloading is one of the common unsafe practices forklift operators do we’ve observed over the years in this business.

- When lifting, make sure the loads are evenly balanced and distributed – proper weight distribution is the key to make the load secure during transport. When loading the goods, the heaviest ones should be as closed to the truck’s mast. One important advice when loading large rectangular boxes is that the boxes should be arranged widthwise and not the other way around, the idea is to prevent the load center from shifting forward that could cause the forklift tip over.

- Refueling or recharging must be performed in a well-ventilated location - Many of us may perceive the refueling/recharging a simple task to do but make no mistake. It is one of the hazardous things you do with a forklift. To avoid an accident during this activity, make sure the forklift is NOT running as it has the probability to cause ignition, and that any naked lights and smoking are strictly prohibited in the refueling location. When recharging an electric forklift, please do remember that recharging should be done only when the charge capacity reaches below 30%. Avoid over and undercharging of the forklift battery as it shortens its lifespan. The charging facility must be equipped with first-aid devices and a wash station in case the battery acid comes in contact with the eyes or skin.

- Park the forklift in a designated area – when work shift ends, park the forklift in a designated location, the company usually assigned a place for this. When shutting down the truck, lower the forks touching the ground and that the parking brake is pressed before leaving. Do not leave the key in the ignition. Don’t park the equipment near the emergency door or exit or in the fire lane as it can block the movement of the vehicle in and out of the premises.

To Wrap This Up

You can ask your coworkers or someone who is trained to operate a forklift to show you these forklifts controls. You can sit beside him as he teaches you where are the controls are in the forklift and its individual function.

After understanding each control and its individual function, you can do practice driving the forklift in an open area where there no people or something you can bump into.

The best way to learn driving a forklift is to it in actual with someone who can teach you. Sit in a forklift, get a good sense of how the forklift controls work. After that, you are on your way driving solo.

Car Dashboard Symbols

Image Attribution: By U.S. National Guard photo by Lt. Col. James Freehart/Released (https://www.dvidshub.net/image/1673683) [Public domain], via Wikimedia Commons